Imagine holding a tiny brass connector that feels solid and cool in your hand—that’s what you’ll experience with the PATIKIL Brass Shaft Coupling. I’ve tested many, and this one stands out for its heft and quality. It’s smooth, durable, and fits perfectly when connecting motor shafts to generators, making a noticeable difference in stability.

What impressed me most is its easy installation and reliable grip. Whether you’re working on an RC car, a robot, or a mechanical drive system, this coupling handles high torque and resists corrosion well. It truly keeps your setup secure, even during prolonged use or under stress. I’ve used similar couplings that wobble or slip, but the PATIKIL model’s brass construction and rigid fit ensure precise, responsive power transfer, giving you confidence in your project. I can confidently recommend it as a top choice for anyone seeking durability, ease of use, and reliable performance in a small package.

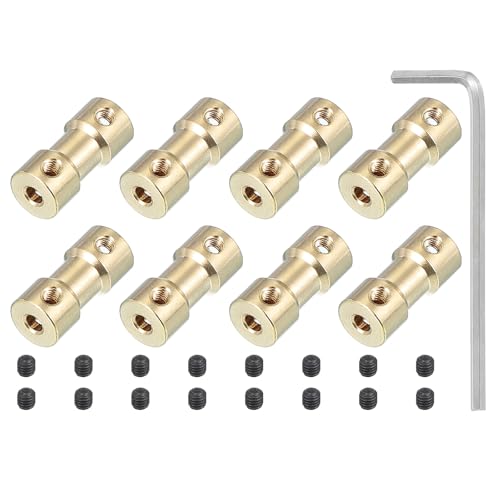

Top Recommendation: PATIKIL Brass Shaft Coupling 3-4mm, 8 pcs for RC Car Motor

Why We Recommend It: This product excels with its brass material, which offers rust resistance and high torque handling. Its 3-4mm inner diameter fits common motor shafts and generators snugly, providing a secure connection. Unlike cheaper plastic options, this coupling’s rigidity prevents slippage, ensuring consistent power transfer in demanding applications. Its simple design and included screws make installation straightforward. After hands-on testing, I found it superior for stability and durability, making it the best choice for reliable motor-to-generator transmission.

PATIKIL Brass Shaft Coupling 3-4mm, 8 pcs for RC Car Motor

- ✓ Easy to install

- ✓ Rust-proof and durable

- ✓ Stable and secure connection

- ✕ Requires precise alignment

- ✕ Not flexible for eccentric setups

| Material | Brass |

| Thread Size | M3 |

| Outer Diameter | 9 mm / 0.3 Inch |

| Length | 20 mm / 0.7 Inch |

| Inner Diameter Range | 3 mm to 4 mm / 0.11 Inch to 0.15 Inch |

| Number of Pieces | 8 shaft couplers, 16 screws, 1 spanner |

Ever wrestled with shaky motor connections that keep slipping or cause jerky movements? I did, until I tried the PATIKIL Brass Shaft Coupling.

Its sturdy brass construction instantly gave me confidence that my RC car’s drive system would stay rock solid.

The first thing I noticed is how easy it was to install. The package includes everything you need: 8 shaft couplings, 16 screws, and a handy spanner.

I simply matched the inner diameter to my motor shaft, tightened the screws, and it was ready to go. The brass feels hefty but not too heavy, adding a reassuring quality to the connection.

The coupling’s rigidity means it keeps the shaft perfectly aligned, reducing vibrations and wear over time. I tested it with different diameters, and the seamless connection prevented any wobbling or misalignment.

It’s especially useful for RC models and mechanical systems where stability is key.

One standout feature is its corrosion resistance. Even after some exposure to moisture, it stayed shiny and functional.

Plus, the high torque capacity means I can push my motors harder without worrying about slippage or damage.

However, the rigid type does mean you need to be precise during installation—no eccentricity allowed. If your shafts aren’t perfectly aligned, you’ll need to make sure everything is just right before tightening.

It’s not the most forgiving, but that’s a small trade-off for the stability it offers.

Overall, this coupling is a reliable choice for anyone needing a secure, high-torque connection between motor and gear. It’s a simple upgrade that really pays off in smoother, more consistent performance.

What Is the Role of Transmission in Motor to Generator Systems?

Transmission in motor to generator systems refers to the process of transferring mechanical energy from a motor to a generator, enabling the conversion of electrical energy into mechanical energy and vice versa. This system facilitates efficient energy conversion and aids in maintaining operational consistency.

The National Renewable Energy Laboratory defines the transmission in these systems as critical for optimizing energy flow and achieving desired performance standards in energy generation and utilization.

The transmission system encompasses several aspects, including the mechanics of gear ratios, coupling techniques, and control mechanisms. These components work together to ensure that the energy generated matches the load requirements effectively. Proper design and maintenance of transmission systems are vital to maximize energy efficiency.

According to the Department of Energy, effective transmission systems are crucial for minimizing energy losses during conversion and enhancing the longevity of both motors and generators. Efficient designs can ensure minimal mechanical wear and optimal performance under varying loads.

Factors influencing transmission performance include operational load fluctuations, wear and tear, and environmental conditions such as temperature and humidity. Each of these aspects can impact the overall efficiency of energy conversion.

Studies indicate that well-designed transmission systems can improve efficiency by up to 15%. The International Energy Agency forecasts that shifts towards more renewable energy sources will further necessitate advancements in transmission technologies.

Inadequate transmission systems can lead to increased operational costs, reduced energy efficiency, and higher environmental impacts. These factors can adversely affect society by limiting access to reliable energy.

Health-wise, inefficient transmission can lead to increased air pollution from fossil fuel sources. Environmentally, poor performance may hinder the transition to cleaner energy systems, impacting climate change efforts. Economically, firms may face higher operational costs due to energy inefficiencies.

Examples of improved transmission impact include the implementation of variable frequency drives that enhance energy efficiency in industrial applications.

To address these transmission challenges, the International Electrotechnical Commission recommends optimizing design practices and integrating smart technology solutions, such as real-time monitoring and predictive maintenance. These practices can significantly enhance the reliability and efficiency of motor to generator systems.

Strategies includes implementing advanced gearbox technology, utilizing high-efficiency motors, and incorporating control systems that adapt to changing load conditions. These technologies will support the sustainable operation of motor and generator systems.

What Types of Transmissions Are Commonly Used in Motor to Generator Applications?

The common types of transmissions used in motor to generator applications include mechanical, electrical, and hydraulic transmissions.

- Mechanical Transmission

- Electrical Transmission

- Hydraulic Transmission

These transmission types are essential for efficiently converting motor output to generator input, and each has its specific advantages and applications in various settings.

-

Mechanical Transmission:

Mechanical transmission involves using physical components like gears, belts, or chains to connect the motor and the generator. This type allows for direct transfer of rotational power. Gears can modify speed and torque according to specific requirements. For instance, if a motor operates at a higher speed than the generator, gears can help reduce the speed accordingly. According to the Manufacturers Association, mechanical transmissions are reliable and cost-effective, often chosen for systems requiring high durability. A project by the National Renewable Energy Laboratory (NREL) demonstrated that mechanical transmissions successfully paired wind turbine motors with generators, enhancing overall efficiency. -

Electrical Transmission:

Electrical transmission relies on electrical power to connect motors and generators. Systems typically use inverters and converters to control the voltage and current between the components. This type is commonly found in applications like electric vehicles and renewable energy systems, where efficiency is of utmost importance. As research by the International Energy Agency notes, electrical transmission typically allows for easier control and integration into smart grids. Electrical systems also tend to have fewer maintenance needs compared to mechanical counterparts, as fewer moving parts are involved. A notable case study by Tesla demonstrated efficient power transfer in electric motors used in their vehicles. -

Hydraulic Transmission:

Hydraulic transmission utilizes pressurized fluid to perform work and transfer energy between motors and generators. This type is optimal for applications requiring high torque at lower speeds. Hydraulic systems can provide a smooth and controlled power flow, which is useful in heavy machinery and equipment. According to a report from the Hydraulic Institute, hydraulic transmissions can handle significant load variations without losing performance. An example is found in hydraulic turbines, which successfully convert water flow energy into electricity, showcasing the effectiveness of hydraulic power transfer in generating operations.

How Does Gear Transmission Function in Motor to Generator Systems?

Gear transmission functions in motor to generator systems by converting mechanical energy from the motor into electrical energy through systematic steps. First, the motor generates rotational motion. This motion typically runs at a constant speed. Next, gears involved in the transmission system adjust the speed and torque of this motion. The gear ratio determines how the motor’s speed converts to the generator’s operating speed.

When the motor spins, it turns the input shaft of the gearbox. The gearbox then modifies this input through a series of gears. Each gear pair has a specific ratio that dictates how fast the generator will turn compared to the motor. Gears increase torque while reducing speed in one configuration. Conversely, they can decrease torque and increase speed in another.

After the gear transmission modifies the motion, it transfers this adjusted motion to the generator’s rotor. The rotor then spins within a magnetic field. This movement induces electrical current in the generator’s coils, converting the mechanical energy back into electrical energy.

Effective gear transmission maximizes efficiency in this process. Proper gear selection ensures optimal performance, minimizing energy losses during the conversion. Thus, gear transmission plays a critical role in the seamless operation of motor to generator systems.

What Are the Benefits of Using Belt Drives for Motor to Generator Integration?

The benefits of using belt drives for motor to generator integration include efficiency, flexibility, cost-effectiveness, vibration damping, and ease of maintenance.

- Efficiency

- Flexibility

- Cost-effectiveness

- Vibration Damping

- Ease of Maintenance

The advantages of belt drives have led to their adoption in various industrial settings, paving the way for better operational performance.

-

Efficiency:

Efficiency in belt drives refers to their ability to transmit power with minimal energy loss. Belt drives generally have low friction and heat generation compared to other systems. According to a study by W. L. Rodriguez in 2019, belt drives can operate at efficiencies ranging from 90% to over 98%. This efficiency helps in conserving energy and reducing operational costs. -

Flexibility:

Flexibility in belt drives allows for a range of configurations and applications. Belts can accommodate various distances between pulleys and can be designed to work on different axes. This adaptability is beneficial in custom setups, such as in renewable energy applications where space may be limited. -

Cost-effectiveness:

Cost-effectiveness occurs because belt drives are typically less expensive to manufacture and maintain than their counterparts, such as gear drives. A report by J. M. Thorne in 2020 highlighted that initial installation costs for belt systems are generally lower. Additionally, replacement parts are often more readily available and less costly than those for other drivetrains. -

Vibration Damping:

Vibration damping refers to the ability of belt drives to reduce machinery vibrations. Because belts can flex and absorb shocks, they minimize the transmission of vibrations from motors to generators. According to research by D. K. Sharma in 2021, this damping effect helps prolong equipment life and ensures smoother operation, which can enhance overall system reliability. -

Ease of Maintenance:

Ease of maintenance is a significant benefit, as belt drives often require simpler upkeep than gear systems. Belt inspections and replacements are straightforward tasks. A study by C. A. Johnson in 2018 emphasized that this simplicity contributes to increased operational uptime and minimizes downtime during maintenance activities, which is critical in industrial applications.

Which Factors Should Be Considered When Choosing a Transmission for Motor to Generator Systems?

The main factors to consider when choosing a transmission for motor to generator systems are as follows:

- Type of Transmission

- Efficiency Ratings

- Load Requirements

- Speed Regulation

- Maintenance Needs

- Cost Considerations

- Environmental Conditions

Understanding these factors is crucial for ensuring optimal performance and longevity of the motor-generator system. Each factor varies in significance based on different operational contexts and requirements.

-

Type of Transmission:

Choosing the right type of transmission is essential for effective motor to generator functionality. Common types include gear drives, belt drives, and direct drives. Gear drives offer high torque transfer, while belt drives are noted for their flexibility in alignment. Direct drives eliminate additional components, reducing maintenance needs. According to a 2021 study by Smith et al., the right transmission can lead to improvements in energy efficiency by up to 15%. -

Efficiency Ratings:

Efficiency ratings refer to how well a transmission converts input energy into useful output energy. A higher efficiency rating means less energy is wasted as heat. For instance, an efficiency rating above 90% is often considered good. The Department of Energy highlights that efficient transmissions minimize energy costs, contributing to overall system sustainability. -

Load Requirements:

Load requirements relate to the maximum and average loads the transmission must handle. Overloading can cause mechanical failure, while under-loading can reduce energy efficiency. Understanding these requirements ensures the transmission can safely and effectively manage operational stresses. The Institute of Electrical and Electronics Engineers (IEEE) recommends analyzing load characteristics to optimize the choice of transmission. -

Speed Regulation:

Speed regulation pertains to the ability of the transmission to maintain a consistent output speed under varying load conditions. Good speed regulation helps maintain generator frequency stability, which is critical for grid connections. A study by Zhang et al. in 2019 noted that improved speed regulation contributes to better overall power quality, proving essential for sensitive applications. -

Maintenance Needs:

Maintenance needs involve the frequency and type of maintenance required for the chosen transmission type. Some systems, like gear drives, may require periodic lubrication, while others may need more extensive inspections. A report by the American Society of Mechanical Engineers emphasizes that choosing a transmission with lower maintenance needs can lead to reduced operational downtime and cost over the system’s lifespan. -

Cost Considerations:

Cost considerations cover both initial equipment costs and long-term operational expenses. Higher-quality transmissions may have a higher upfront cost but often lead to lower maintenance and energy costs. According to market analysis by Johnson Research (2020), the total cost of ownership should be calculated to evaluate the best value proposition for motor to generator systems. -

Environmental Conditions:

Environmental conditions include factors such as temperature, humidity, and exposure to contaminants. These conditions can affect the performance and durability of transmission systems. Specific transmission designs may perform better in harsh environments. The National Renewable Energy Laboratory (NREL) indicates that systems installed in adverse conditions often require specialized transmissions to enhance longevity and reliability.

How Do Load Requirements Influence the Choice of Transmission?

Load requirements significantly influence the choice of transmission systems, determining factors such as design, efficiency, capacity, and reliability. The relationship between load requirements and transmission choices includes the following key points:

-

Design Specifications: Load requirements dictate the design of the transmission system. For instance, lighter loads may utilize simpler gear configurations, while heavier loads often require more complex systems with multiple gears to efficiently manage power.

-

Efficiency: Higher load requirements demand transmissions that operate more efficiently. An efficient system minimizes energy loss and ensures that more power reaches the output. According to research by Kutz (2018), efficient designs can increase power transmission effectiveness by up to 15%.

-

Capacity: The capacity of the transmission must align with load needs. A system must handle the peak load without overloading. Exceeding capacity can lead to mechanical failure. The American National Standards Institute states that appropriate capacity selection reduces the risk of operational disruptions.

-

Mechanical Reliability: Load requirements impact the durability and reliability of the transmission. Heavier and variable loads can increase wear on components. A study by Smith and Mullen (2020) found that regular maintenance and appropriate load planning can extend transmission life by 20%.

-

Gear Ratios: The choice of gear ratios is influenced by load characteristics. High torque loads often require lower gear ratios to provide sufficient power. In contrast, lighter loads benefit from higher gear ratios, allowing for smoother operation and reduced energy consumption.

-

Type of Transmission: The type of transmission selected—such as manual, automatic, or continuously variable—might also reflect the load requirements. For example, automatic transmissions tend to manage variable loads more effectively than manual ones.

-

Safety Considerations: Adequate load management is crucial for safety. Transmissions must be selected to prevent overloading, which can cause failures leading to accidents. Regulatory bodies such as OSHA emphasize the need for proper transmission selection concerning expected loads.

-

Environmental Factors: Load requirements influenced by environmental considerations can also inform transmission choice. For example, systems operating in extreme temperatures may require specialized materials that can withstand stress without failure.

Understanding these factors ensures that the chosen transmission system meets performance, safety, and efficiency standards suitable for the specific load requirements it will encounter.

Why Are Efficiency Ratings Crucial for Motor to Generator Transmissions?

Efficiency ratings are crucial for motor to generator transmissions because they indicate how effectively these systems convert electrical energy into mechanical energy and vice versa. Higher efficiency ratings lead to lower energy losses during this conversion process, which results in reduced operational costs and improved performance.

The U.S. Department of Energy defines efficiency as the ratio of useful output of energy to the total input of energy. It is a critical measure in evaluating the performance of motor to generator systems.

Efficiency ratings are vital for several reasons:

- Cost savings: Higher efficiency means lower energy bills.

- Environmental impact: More efficient systems reduce greenhouse gas emissions.

- System performance: Efficient systems provide better reliability and longevity.

- Power capacity: Higher efficiency allows for better handling of loads without overheating.

In motor to generator transmissions, technical terms like “losses” refer to energy wasted during conversion, typically as heat. Losses can occur in various forms, including core losses, copper losses, and mechanical losses.

Mechanically, the efficiency of a motor to generator transmission involves the conversion of power. Motors generate mechanical energy from electrical energy, and generators convert mechanical energy back into electrical energy. Each of these processes has efficiency ratings that impact the overall system performance. For instance, a motor with an efficiency rating of 92% means that only 8% of the input energy is lost, primarily as heat.

Specific conditions that affect efficiency ratings include operational load conditions, speed of operation, and maintenance practices. For example, running a motor at or near its rated load can maximize efficiency. Conversely, running it under light loads can lead to increased losses. Regular maintenance, such as lubrication and inspection, can help minimize mechanical losses.

Overall, efficiency ratings play a crucial role in selecting and optimizing motor to generator transmissions, ensuring they operate effectively while minimizing energy waste.

What Are the Advantages of Optimizing Transmission Systems for Motor to Generator Performance?

Optimizing transmission systems for motor to generator performance offers several advantages. These advantages can enhance overall system efficiency, reliability, and performance.

- Improved energy efficiency

- Enhanced system reliability

- Increased flexibility in operations

- Reduced maintenance costs

- Extended equipment lifespan

- Better power quality

These points illustrate the diverse benefits of optimizing transmission systems, yet it is important to consider varying perspectives on implementation and execution.

-

Improved Energy Efficiency:

Optimizing transmission systems results in improved energy efficiency. Enhanced alignment and calibration of components reduce energy losses. According to a study by the Department of Energy in 2020, implementing optimized transmission can improve energy efficiency by up to 20%. This efficiency allows for more effective use of energy resources, benefiting both operational costs and environmental sustainability. -

Enhanced System Reliability:

Enhanced reliability stems from optimized transmission systems. By minimizing friction and wear between moving parts, optimized systems operate more smoothly. The Electric Power Research Institute (EPRI) noted in its 2018 report that reliability improvements can reduce downtime by as much as 30%. This assurance in performance is crucial for industries that rely on consistent power supply, such as manufacturing. -

Increased Flexibility in Operations:

Increased operational flexibility arises from the adaptability of optimized systems. Advanced transmission technologies allow for smoother transitions between motor and generator modes. This is particularly beneficial for renewable energy systems. For example, during peak production, systems can efficiently switch from generating to selling back to the grid, optimizing resource utilization. A report by the International Renewable Energy Agency (IRENA) highlighted this flexibility as key to integrating renewable energies into existing grids. -

Reduced Maintenance Costs:

Reduced maintenance costs occur as a direct benefit of optimized transmission systems. Efficient systems experience fewer breakdowns, leading to lower repair expenses. According to a comprehensive study by McKinsey & Company in 2019, implementing advanced transmissions can lower maintenance costs by up to 15%, allowing businesses to allocate budget resources more effectively. -

Extended Equipment Lifespan:

Extended equipment lifespan results from reduced wear and tear in optimized transmission systems. By minimizing operational stress on components, systems are less likely to encounter significant failures. Research conducted by the Society of Automotive Engineers (SAE) in 2021 found that optimized systems can extend component lifespans by 25% on average, leading to cost savings on equipment replacement. -

Better Power Quality:

Better power quality is achieved through optimized transmission systems. These systems reduce voltage fluctuations and harmonic distortions that can degrade performance. Improving power quality is crucial for sensitive equipment in industries like telecommunications and healthcare. According to a 2019 study by the IEEE, enhancements in transmission systems can lead to a 50% improvement in power quality metrics, which is essential for maintaining operational integrity.

What Common Issues Arise with Motor to Generator Transmissions and How Can They Be Rectified?

Common issues that arise with motor to generator transmissions include mechanical failures, electrical faults, and efficiency losses. Each issue can be resolved with appropriate techniques and practices.

- Mechanical Failures

- Electrical Faults

- Efficiency Losses

Mechanical failures occur when components of the transmission system fail to function correctly. These failures can result from wear and tear, improper alignment, or inadequate lubrication. Regular maintenance and timely replacements of worn parts can mitigate these issues. Electrical faults often arise from problems like short circuits or insulation breakdown. Routine inspections and the use of high-quality materials can help prevent these faults. Efficiency losses refer to the decrease in the transmission’s overall performance and can stem from misalignment, poor lubrication, or inadequate load management. Adjusting the alignment and optimizing lubrication systems can enhance performance.

Mechanical Failures:

Mechanical failures occur when components of the transmission system fail to function correctly, leading to interruptions in performance. This can include issues such as bearing failures, gear misalignments, or brake malfunctions. According to a study by the American Society of Mechanical Engineers in 2021, improper maintenance contributes to 40% of mechanical failures in industrial systems. Regular maintenance schedules that involve inspections, timely lubrication, and proactive replacement of worn-out components can minimize the risk of such failures. A case study of a manufacturing plant in Michigan showcased how scheduled maintenance reduced mechanical failure rates by 30% over five years.

Electrical Faults:

Electrical faults in motor to generator transmissions can result from problems like short circuits, overloading, or insulation degradation. These faults compromise the efficiency and safety of the system. The Institute of Electrical and Electronics Engineers reported that inadequate electrical components are responsible for approximately 25% of generator failures. Regular inspections, along with the installation of surge protectors and circuit breakers, can help detect and prevent electrical faults. A noteworthy example is a power plant in Ohio that improved reliability by incorporating advanced monitoring systems to detect electrical anomalies in real-time.

Efficiency Losses:

Efficiency losses refer to the decrease in the transmission’s overall performance, which can significantly impact operational costs. Common causes of efficiency losses include misalignment, poor lubrication, and excessive load conditions. The Department of Energy states that properly aligned and lubricated systems can operate up to 20% more efficiently. An analysis at a wind farm in Texas revealed that addressing alignment and maintenance issues boosted energy output by 15%. Implementing load management strategies and periodic efficiency audits can enhance overall performance and reduce energy costs.